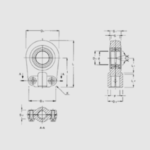

PR..U-N

Female thread stainless steel rod ends

COUPLING:

Chromed stainless steel /PTFE liner NOT requiring maintenance.

Bearing ISO 12240-4, GE..UK-N (ISO12240-1) assembled into shape using circlips. Cut on thread to allow tighter coupling with rod through screw DIN912, class A7.

Lubrication forbidden.

SPECIFICATION:

Shell made in stainless steel AISI316 electropolished. Plain spherical bearing made in AISI420C.

APPLICATION FIELDS:

Rod end to be threaded on hydraulic cylinders rods. Short pitch thread, ideal for space saving without affect cylinder stroke. These rod ends are subjected to electropolishing treatment according to MOCA regulations, which makes them particularly suitable for use in the food sector. Other fields of use can be the chemical and pharmaceutical sectors.

Removable plain bearing for easy substitution and maintenance.

Available version with 2RS seals.

STAINLESS STEEL BALL JOINT ENDS

• MAINTENANCE FREE

• HOUSING MATERIAL: STAINLESS STEEL AISI 316

• BEARING MATERIAL: COUPLING STAINLESS STEEL AISI 420 + PTFE FABRIC

TECHNICAL DATA

| ninjacolumn1 | ninjacolumn2 | ninjacolumn3 | ninjacolumn4 | ninjacolumn5 | ninjacolumn6 | ninjacolumn7 | ninjacolumn8 | ninjacolumn9 | ninjacolumn10 | ninjacolumn11 | ninjacolumn12 | ninjacolumn13 | ninjacolumn14 | ninjacolumn15 | ninjacolumn16 | ninjacolumn17 | ninjacolumn18 | ninjacolumn19 | ninjacolumn20 | ninjacolumn21 | ninjacolumn22 | ninjacolumn23 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TOLLERANZE TOLERANCES | FATTORI DI CARICO KN LOAD FACTORS | |||||||||||||||||||||||

| SIGLA CODE | d | I | S | LF | D1 | D2 | D3 | D4 | DS1 | S2 | L | L1 | F | d mm | D mm | GIUOCO SNODO RADIALE mm RADIAL JOINT CLEARANCE | STATICO CO STATIC CO | DINAMICO C DYNAMIC C | ANGOLO DI OSCILLAZIONE ANGLE OF OSCILLATION | VITI DIN 912 12.9 SCREWS | COPPIA DI SERRAGGIO VITI Nm TORQUE OF SCREWS | PESO Kg. WEIGHT | ||

| PR20UN | 20 | 50 | 16 | 17 | 56 | 46 | 25 | 24.1 | 19 | 21 | 80 | 25 | M16X1.5 | 0÷-0.010 | 0÷-0.12 | 0.030÷0.082 | 41 | 30 | 9° | M8X20 | 25 | 0.4 | ||

| PR25UN | 25 | 50 | 20 | 17 | 56 | 46 | 25 | 29.3 | 23 | 21 | 80 | 28 | M16X1.5 | 0÷-0.010 | 0÷-0.12 | 0.037÷0.100 | 41 | 41 | 7° | M8X20 | 25 | 0.475 | ||

| PR30UN | 30 | 60 | 22 | 23 | 64 | 50 | 32 | 34.2 | 28 | 26 | 94 | 30 | M22X1.5 | 0÷-0.010 | 0÷-0.12 | 0.037÷0.100 | 60.4 | 60.4 | 6° | M8X25 | 25 | 0.7 | ||

| PR35UN | 35 | 70 | 25 | 29 | 78 | 66 | 40 | 39.7 | 30 | 28 | 112 | 38 | M28X1.5 | 0÷-0.012 | 0÷-0.12 | 0.037÷0.100 | 87.2 | 80 | 6° | M10X30 | 49 | 1.15 | ||

| PR40UN | 40 | 85 | 28 | 36 | 94 | 76 | 49 | 45 | 35 | 33 | 135 | 45 | M35X1.5 | 0÷-0.012 | 0÷-0.12 | 0.043÷0.120 | 142.5 | 100 | 7° | M10X35 | 49 | 2.075 | ||

| PR50UN | 50 | 105 | 35 | 46 | 116 | 90 | 61 | 56 | 40 | 37 | 168 | 55 | M45X1.5 | 0÷-0.012 | 0÷-0.12 | 0.043÷0.120 | 208 | 156 | 6° | M12X40 | 86 | 3.575 | ||